Flexible ways of use

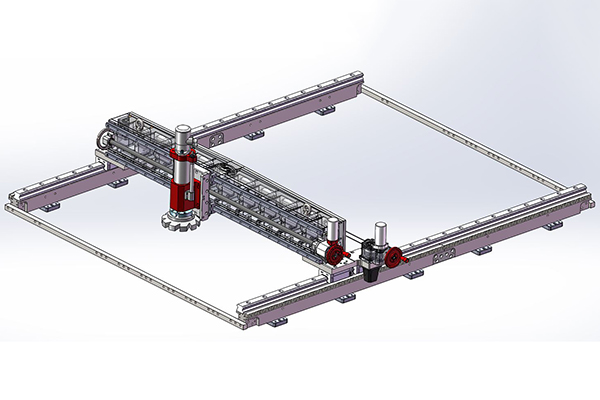

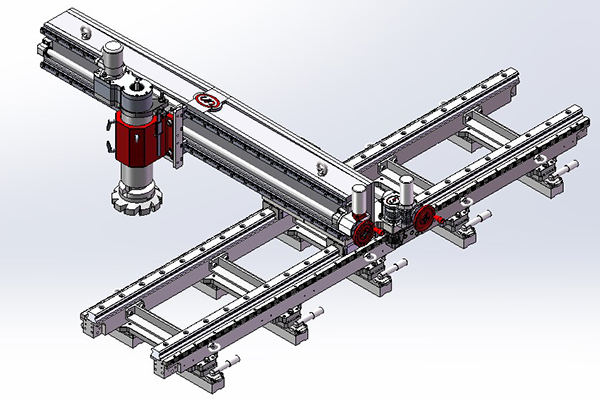

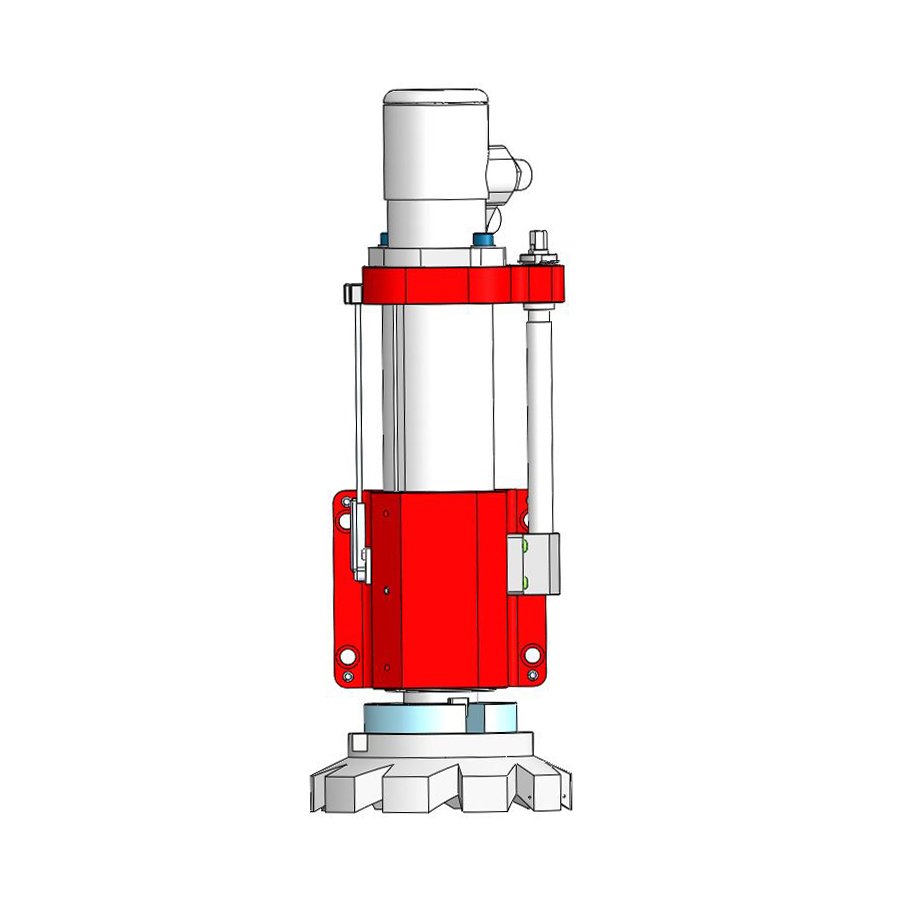

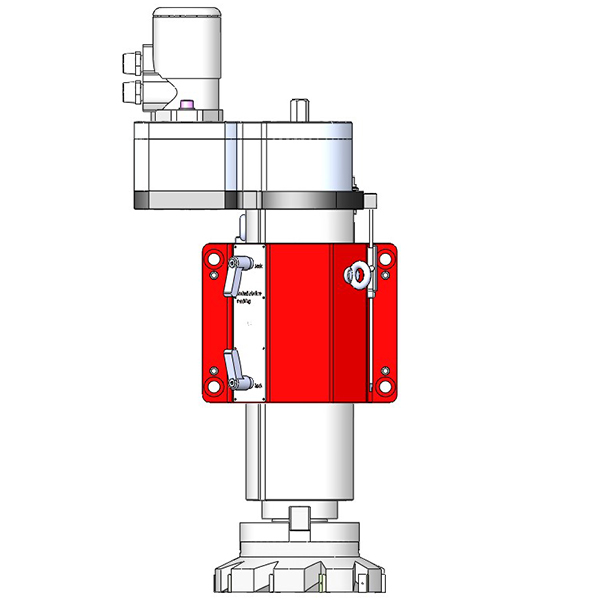

LMD series gantry milling adopts a modular design, each parts can be customized according to the on-site processing requirements for various special functions, such as replacing the bolt-fixed base with a magnetic base, and the X-axis, Y-axis, and Z-axis can be driven by hydraulic, electric or pneumatic power according to actual needs. The milling head can also be replaced with cutter head various sizes to meet the machining needs of milling, drilling, boring, etc.

Safety and efficiency

Modular properties allow it to be moved separately in blocks, increasing safety by avoiding lifting and moving with a bulky whole machine.

Precision

Provides optimal surface finish, allows precision machining of parts, the highest accuracy can reach 0.02mm. .

Superior machining performance

Standard equipped with a 26KW hydraulic power unit, the ability to work in a variety of complex situations, strong power and stable machine body ensure fast machining speed and high precision.

Various application

LMD2000 is commonly used in shipyard hulls and structural parts, wind turbine components, offshore oil and gas drilling platforms, industrial plant surfaces and structures, power generation components such as turbine housings and rotors, rail tracks and rail bridges, hydraulic cylinders, heavy steel beams for construction projects, large valves and flanges, heat exchangers and compressor components, etc.