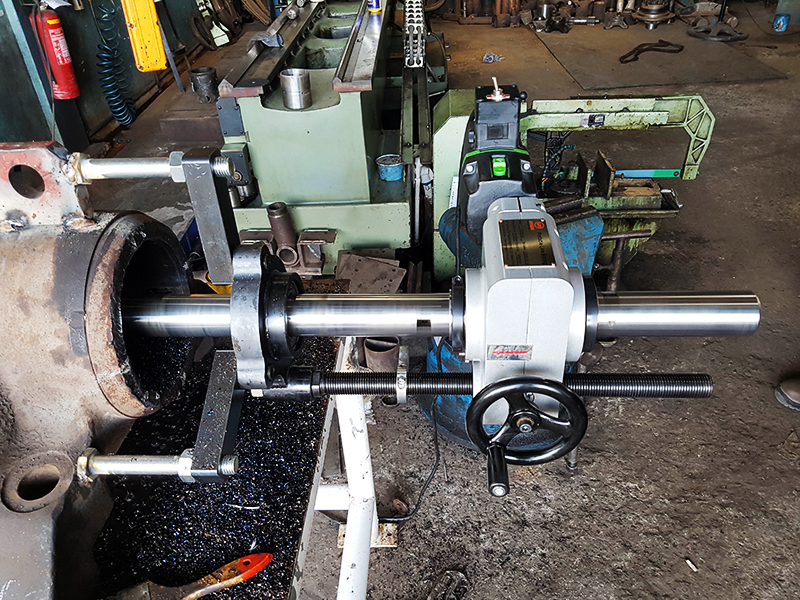

PORTABLE DESIGN

Compact and modular design making it suitable for use in narrow and complex environments. The rotational drive unit and feed unit can be fixed anywhere along the boring bar, and the stepless speed regulation range of 0 to 0.5mm allows for easy forward and reverse exchange.