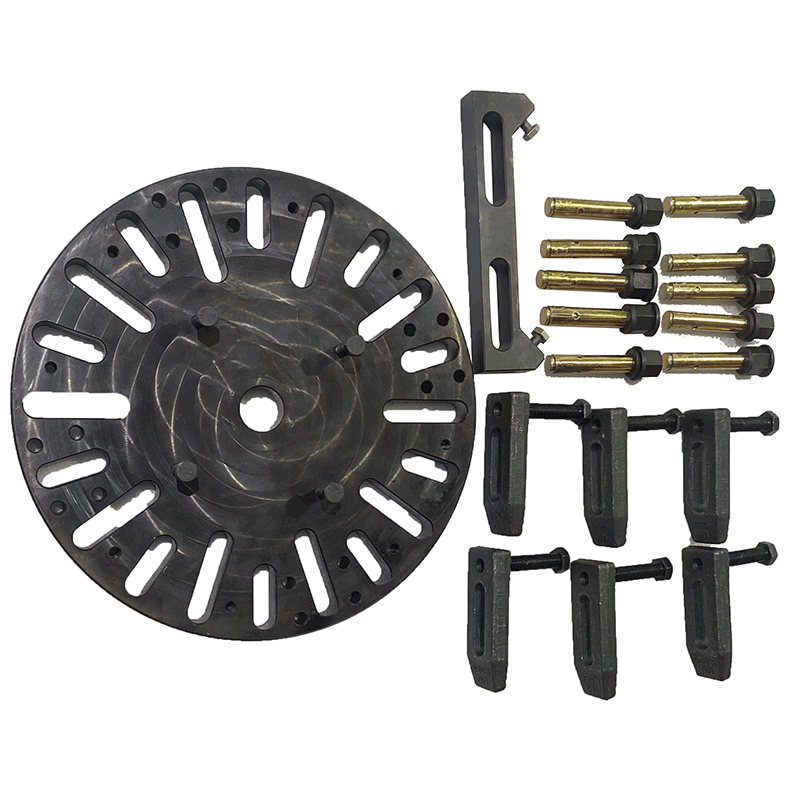

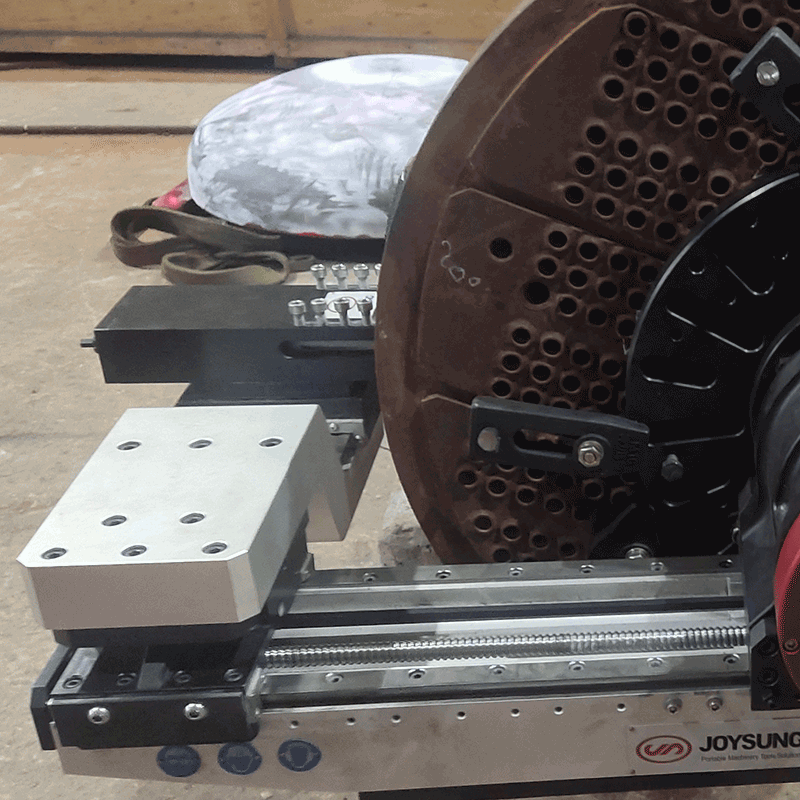

Quick and Easy Setup: The FDG1000 is equipped with three independent and distinct quick set bases of varying sizes, endowing it with enhanced on-site operation capabilities. The bases available in different sizes are aimed at accommodating varying work environments and requirements, reflecting the machine’s adaptability to varying circumstances. The process of selecting and exchanging the appropriate base size is simplified and facilitated for the operator, contributing to improved versatility and adaptability during machining operations at various sites.

Processing versatility: 6 different continuous groove gramophone finishes to ASME Standard. Suitable “O” Ring grooves, Lens ring, RTJ grooves,RF,weld preparations etc.

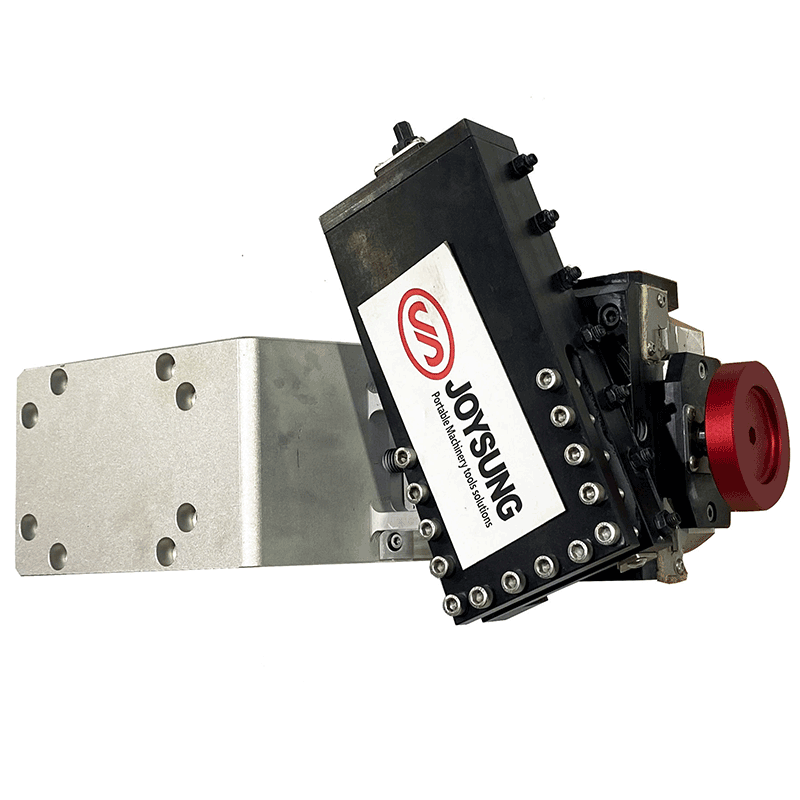

Powerful, Precise Machining Performance: Heavy-duty machining arms provide rigid performance and reliable results, ensuring high-quality cutting performance throughout the full range of the machine. 2.2 HP pneumatic motor provides more power and speed resulting in higher metal removal rates to get the job done fast.