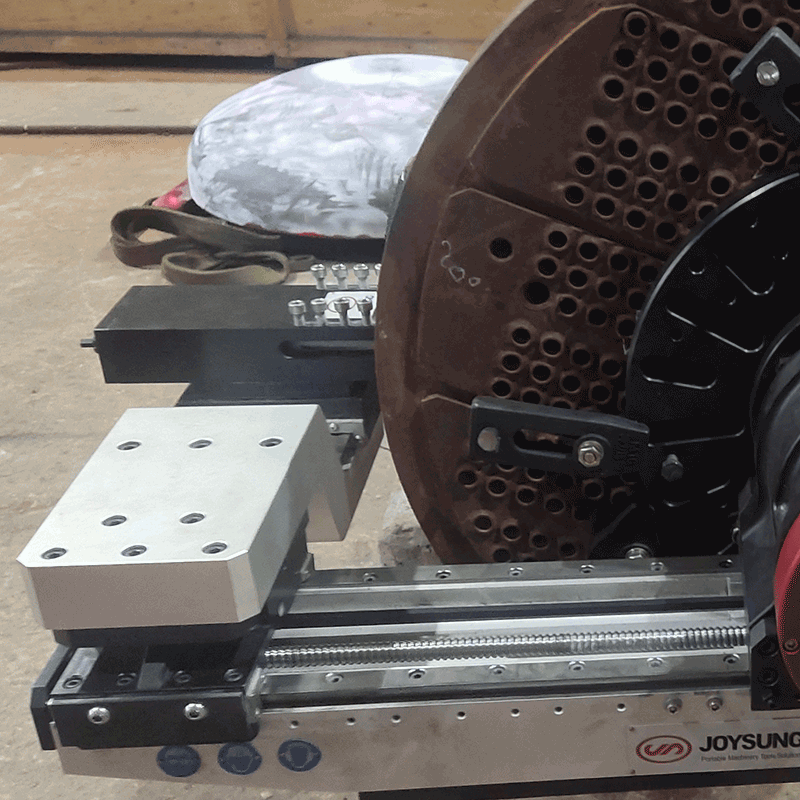

PORTABLE DESIGN

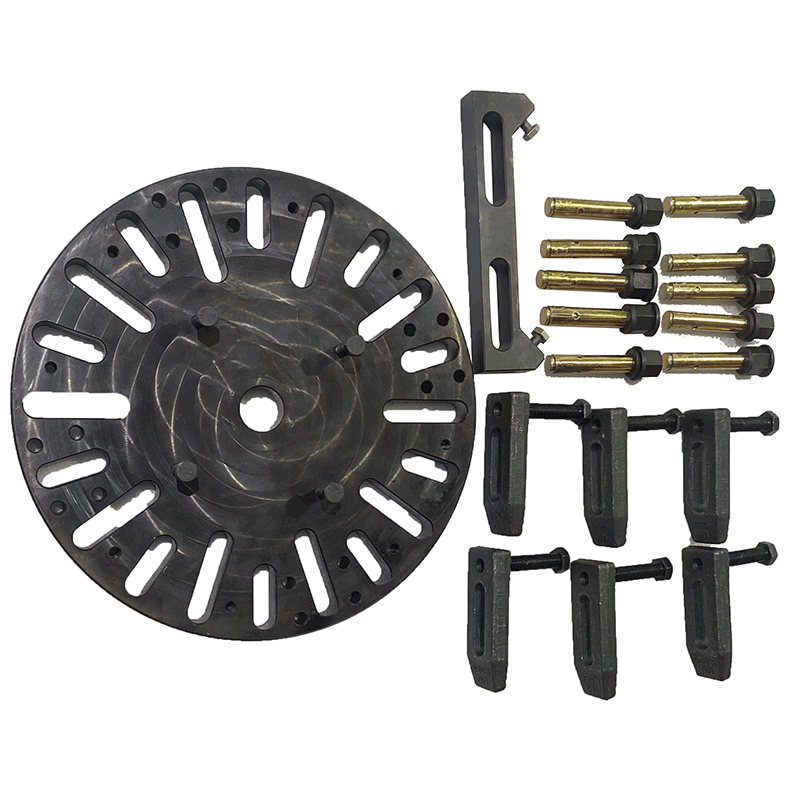

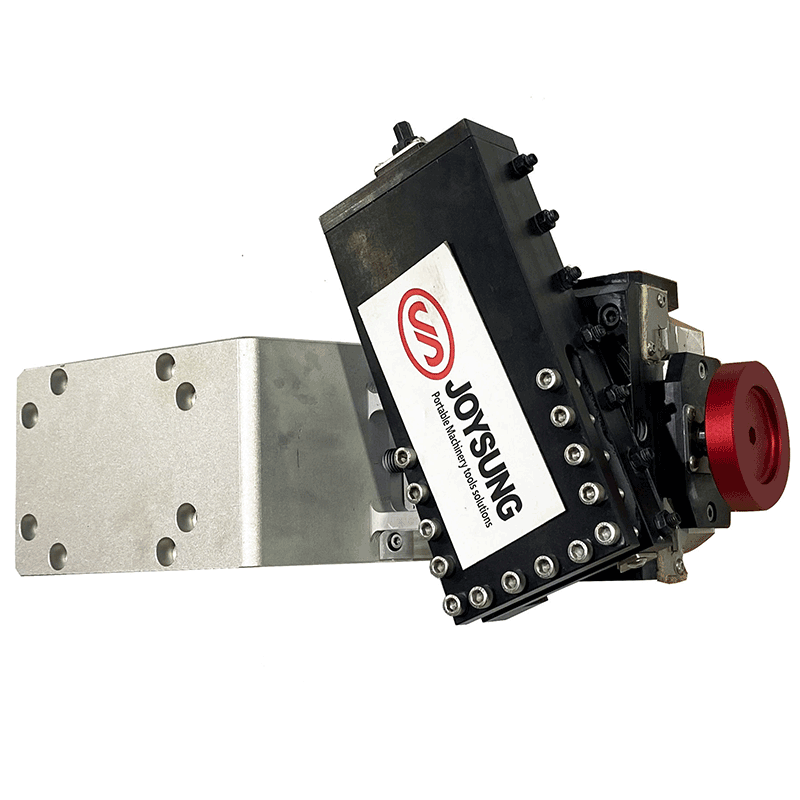

Setting up the machine is made easy with the included 3-leg mount kit, which can be adjusted to different angles to accommodate various hole positions. The machine also comes equipped with measuring tools such as a bore cutter measuring tool and diameter measuring ruler.Only a little training is required to understand the installation and use of the machine.