Reliable and easy to maintain

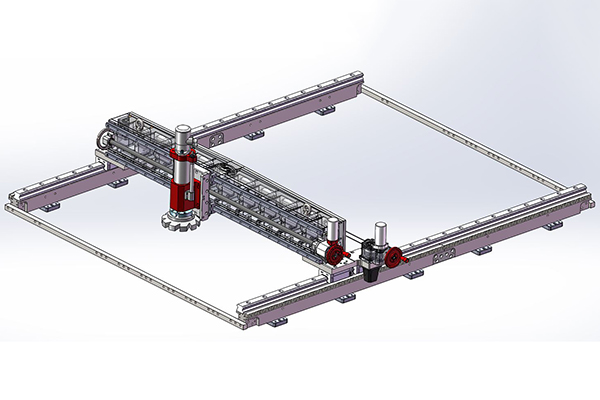

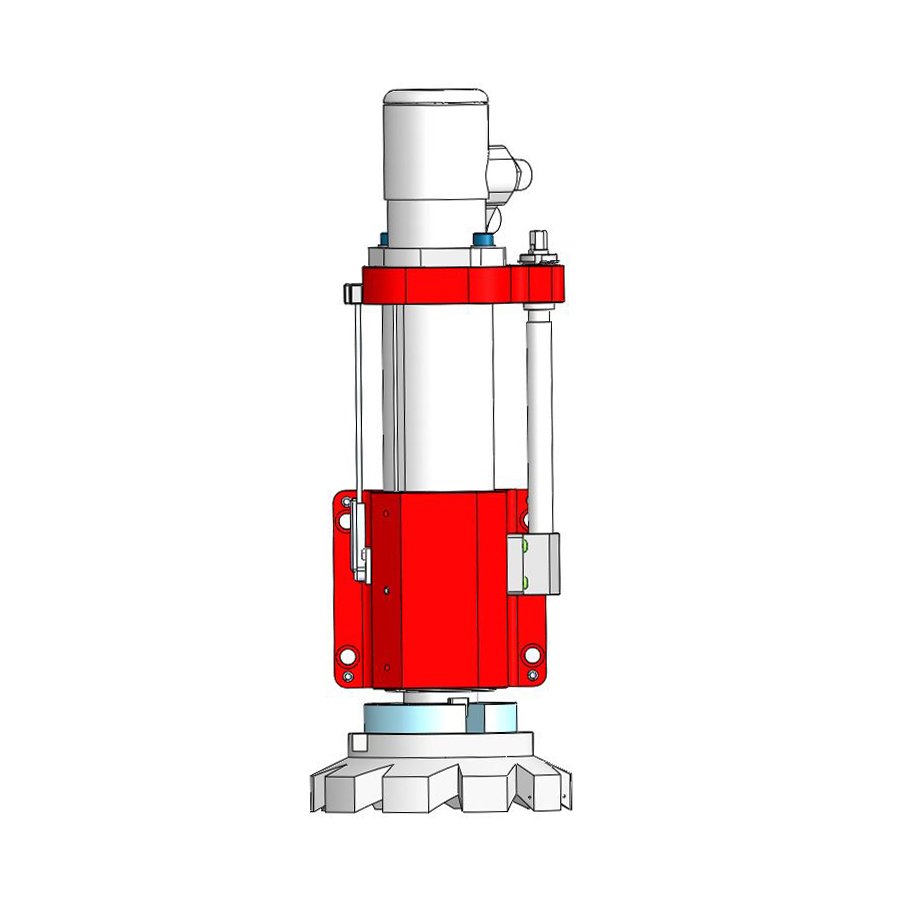

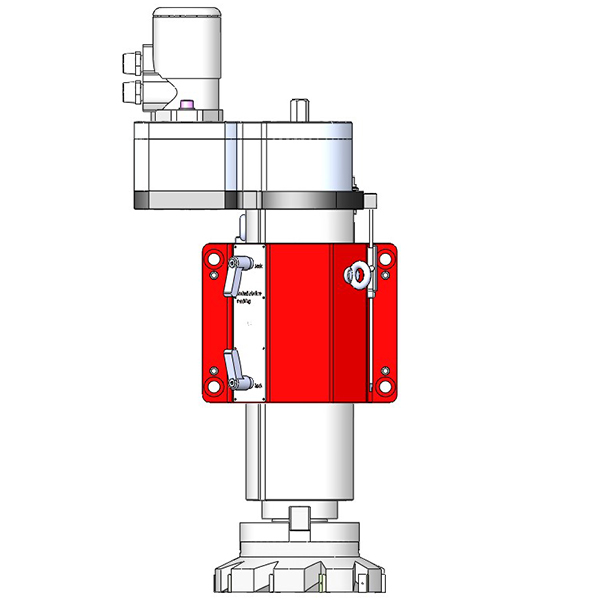

The LMD 3000 series provides flexibility in machining activities, and can easily cope with the following harsh site conditions: narrow space, various orientations machining surface, high altitude operation, etc. Sturdy and simple structure and strong processing capacity ensure that this machine can output stably, complete processing tasks quickly, and require minimal maintenance.

User-friendly

The operation of the LMD series gantry milling machine is simple, and it can be operated alone without much professional training during the processing. The control panel has a total of 5 buttons, which control the X-axis, Y-axis, spindle rotation, switch and Emergency stop switch, and avoid misoperation due to complex operation interface.

Easy to transport

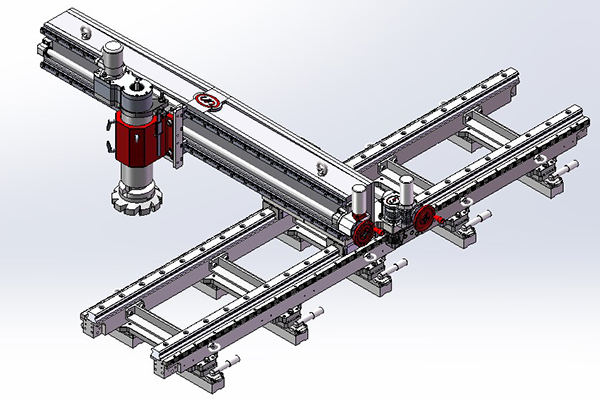

No need for specialized transportation, with its modular design, it can be easily disassembled and transported to remote areas via a pickup truck or family car, effectively reducing the high cost of transportation.

Precise and easy to operate leveling mechanism

The gantry is leveled by adjusting the holding down bolts and jacking screws on both sides of the guide rail, and adjusting the guide rails in sections with a spirit level to achieve optimal leveling without requiring additional instruments.

Specific applications

large forgings and castings, gas turbine parts, nuclear power plant components, power plant maintenance, massive casting equipment components, large building facade components, water processing plant components, large generators and transformers, hydroelectric dam equipment components.