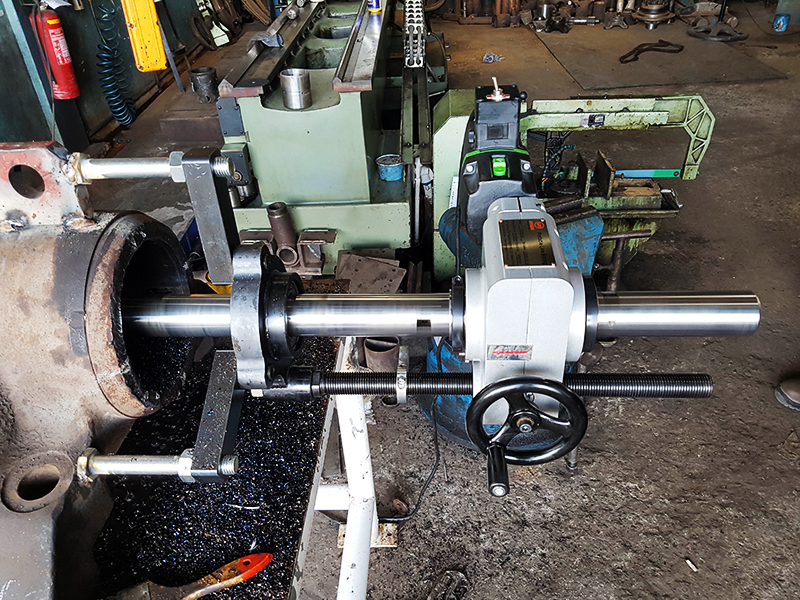

PORTABLE DESIGN

With a compact and portable design, it is easy to move and set up. Its lightweight construction makes it ideal for use in tight spaces, and the machine’s modular design allows it to be optimally processed wherever it is needed.