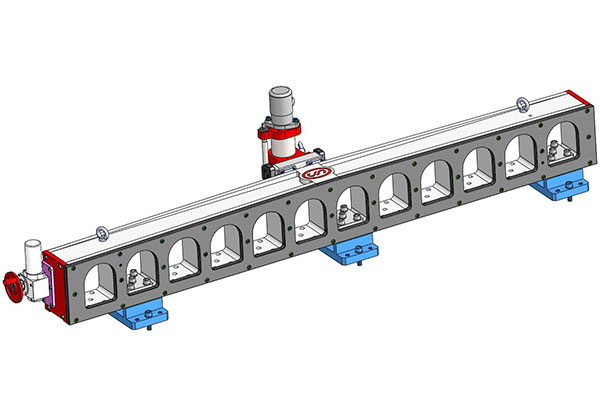

PORTABLE DESIGN

For linear milling within 2000mm, LMA2000 can achieve the body weight of only 350KG, the accuracy can reach 0.02mm. It is unbeatable lightweight and precise.

X axis stroke 2000mm, Z axis stroke 250mm, drive by a 22KW double output hydraulic station.

Commonly used in industries such as shipyards, steel mills, motor bases, heat exchangers, turbine split lines.

PORTABLE DESIGN

For linear milling within 2000mm, LMA2000 can achieve the body weight of only 350KG, the accuracy can reach 0.02mm. It is unbeatable lightweight and precise.

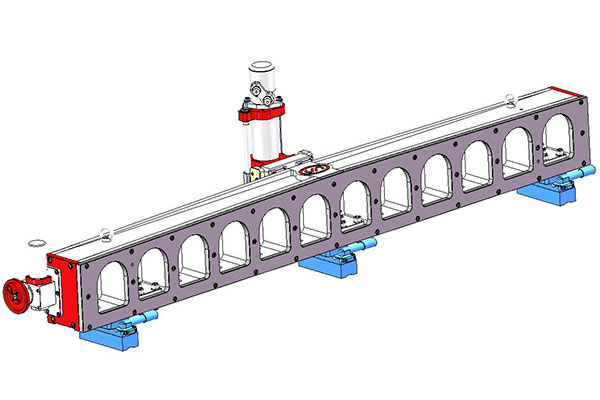

MAIN BED

Main bed consist with:

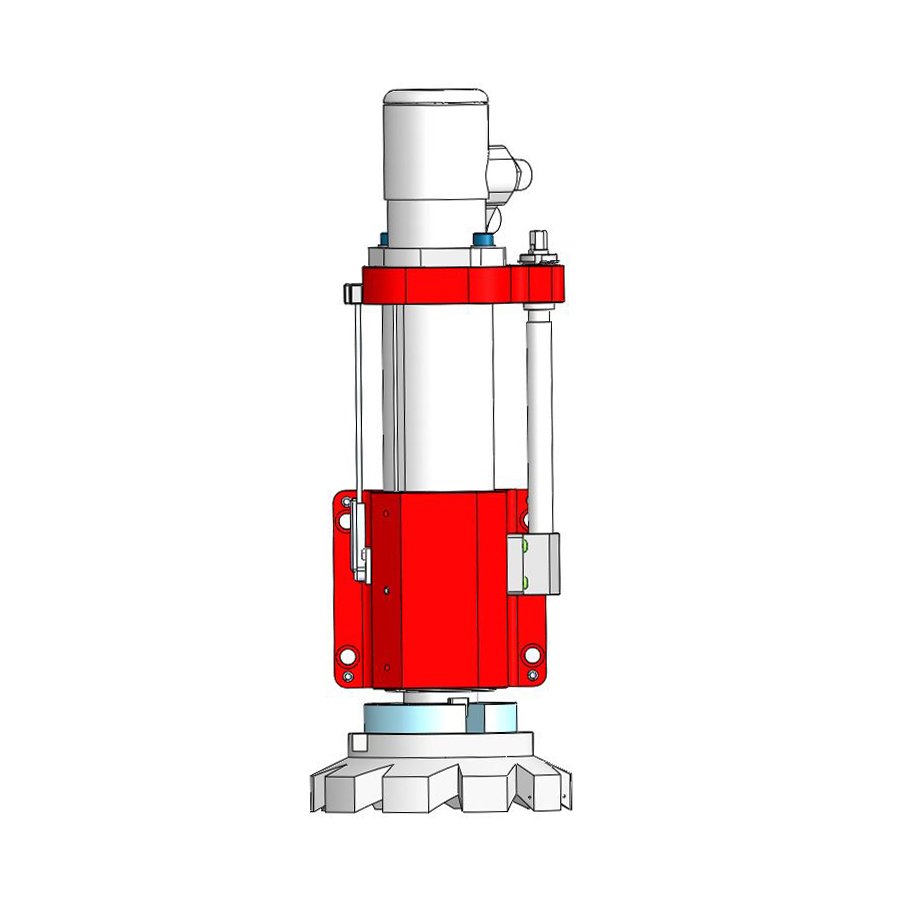

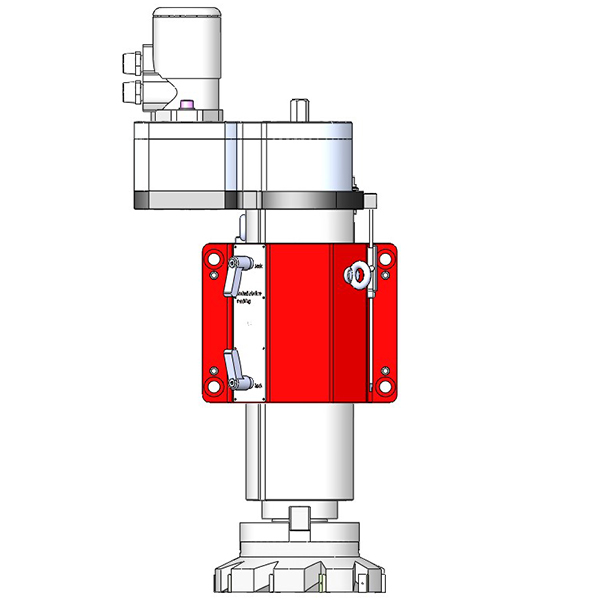

MILLING SPINDLE HEAD

Z axis(Milling spindle head):

cutter diameter: 160mm

cutter diameter: 200mm

MOUNTING BASE

connected machine and workpiece by bolting or welding

connected machine and workpiece by magnetic force

POWER SYSTEM

| Hydraulic Motor Model | Milling RPM |

| 160# | 0-355 rpm |

| 200# | 0-305 rpm |

| 250# | 0-245 rpm |

| Pneumatic Motor (spindle rotation) | Pneumatic Motor (feeding) |

| 3.7KW | 0.89KW |

| 6-8 bar | 6-8 bar |

| 3.56m³/min | 1.3m³/min |

3.7KW, 6-8 bar, 3.56m³/min

0.89KW, 6-8 bar, 1.3m³/min

TOOL PACK

| Code | Name | Unit | Image |

| 104511 | Carbide Tip | Box(10pcs) |  |

| 00000 | Hydraulic Motor | pcs |  |

| 00000 | Quick Connector | pcs |  |

Portable Machine Tool Warranties

All new portable machine tools come with a 12 month warranty as standard. Of course, warranty cover does not mean that a machine tool does not need to be serviced, or that parts will not experience wear and tear and, as a consequence, may need to be replaced.

Extended 2 Year Machine Tool Warranties

Depending on a machine tool’s use and application, customers can also opt for an extended warranty to 2 years to provide extra peace of mind and which can help keep machine downtime and repair costs predictable, and to a minimum.

SHIPPING DATA

| MODEL | DIMENTION(MM) | VOLUME(CBM) | WEIGHT(KG) |

| LMA2000 | Box1: 2700*530*650 | 0.93 | 400 |

| Box2: 1080*940*1460 | 1.49 | 650 | |

| TOTAL | 2.42 | 1050 |

Machine body

Hydraulic station

It can be installed on the workpiece in any orientation, including horizontal, vertical, or inverted. It can also be fixed using magnetic force, bolted, welded, etc. The stroke length of 2000mm is appropriate for most workpiece machining and maintenance needs. It have superior availability of customization which provides flexible computer control options for milling purposes, and portable mobility.

The conventional 22KW dual-output hydraulic system delivers robust and reliable power for processing. The spindle allows for a flexible range of 0-700 rpm, ensuring high precision completion of milling or drilling tasks.

It is equipped with NT40 or NT50 milling head as standard, and adopts universal carbide insert. The bolts are also standard models, which can be found in the market. The consumable parts for daily machining can be bought in your local hardware stores, thereby eliminating the high cost and time consuming trouble caused by custom parts.

| CATEGORY | ITEM | LMA2000 | ||

| STROKE | X Axis(auto) | 2000mm | ||

| Z Axis(manual) | 250mm | |||

| AUTO FEED | Hydraulic | 20L/min | ||

| Pneumatic | 0.89KW, 1.10 m³/min | |||

| Feed Rate | 35-1000mm/min | |||

| MILLING SPINDLE | Hydraulic | 60L/min | ||

| Pneumatic | 3KW 2.69 m³/min | |||

| Spindle Taper | NT40 or NT50 | |||

| Max Cutter Dia. | 160mm(NT40) or 250mm(NT50) | |||

| Spindle R.P.M | 0-740 | |||

| POWER SYSTEM | Hydraulic Station | 22KW | ||

How to select an appropriate portable on-site machining tool? Have you encountered challenges in making this decision? Key factors such as machining precision, machining efficiency, procurement budget, and post-sales support ought to be taken into consideration. Please get in touch with us, we are here for you! We offer global sales and service support, paired with professional sales representatives to assist in effectively resolving any issue.

WORLD HEADQUARTERS

Address: Singports

Phone:

Email: Info@turnafix.com

Please give us a call or complete the contact form, the regional sales manager will promptly reach out to you.